Finding the right hydraulic hose size is essential to ensure system performance, safety and longevity. The wrong hose can cause damage or even a catastrophic failure that could cost lives.

To find a hose size to match a flow rate and recommended flow velocity, locate the corresponding points on the Pressure Lines Maximum Recommended Flow Velocity chart. A straight line across these two points will cross Hose Bore on the centre scale.

Inner Diameter

The inner diameter (ID) is the empty space in a circular hose cross section through which hydraulic fluid passes. Getting the ID right is critical as it has a direct impact on flow velocity. Too small an ID results in sluggish system performance, while too large an ID leads to excessive pressure drops and leaks.

The ID measurement also impacts how much a hose can handle. An oversized hose has greater friction and is less efficient than a smaller sized hose.

You can find a hose’s ID by reading the lay line on the hose or by using a hydraulic hose sizing nomograph. If the lay line on the hose is worn or otherwise unreadable, remove the hose and cut it to measure its ID before ordering a replacement. This will require determining the cut length by subtracting the distance from the end of each fitting collar to its internal sealing surface. This should be done carefully to avoid damaging the hose or making it inoperable.

Outer Diameter

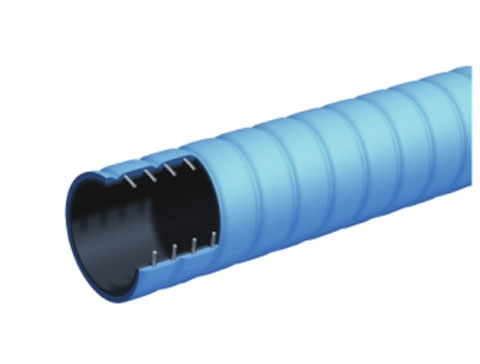

There are a lot of different hydraulic hoses out there. Some of them are made to be as flexible as a telephone long-distance line and others are reinforced with steel wires for maximum strength. These varying specifications make it challenging to choose the right hydraulic hose for a particular application.

The most important factor is the inner diameter of the hose (ID). This determines the flow velocity and system performance. An oversized ID leads to sluggish flow, while an undersized ID can result in excessive pressure drops and possible damage to the system components.

To find the correct ID, check the hose layline – the line running along the length of the hose with all of the numbers and letters on it. Locate the flow rate in the left column and the recommended velocity in the right column. Use a straight edge to lay across these values and intersect them to reveal the dash size.

Length

Hydraulic hoses are designed for specific environments, pressures and fluids. They also vary based on their internal configuration; the number of wire braids in the rubber, ferrule and end fittings used. For example, R2T hoses have 2 wire braids and are rated for low to medium pressures while 4SP hoses have four wire braids and can handle much higher pressures.

The length of a hydraulic hose is important as well. Too short a hose can lead to head loss caused by friction between the hose and its interior walls. Too long a hose can also increase pressure drop in the system as a result of longer distances between the hose’s end points.

Measuring the length of a hydraulic hose can be tricky. It’s best to use a hose cutting tool to ensure the correct cut. When measuring a hose with a male threaded or angled end, make sure you are measuring from the center of the threads or sealing surface to get an accurate measurement.

Pressure Rating

The pressure rating of a hydraulic hose is important because it is the limit for the amount of pressure the hose can handle. If the hose is not rated for the pressure your system will use, it could burst and cause damage or injury.

The pressure ratings of hoses are determined by the number of wire braids, type of rubber, and ferrule or end fittings used. Each hose has a maximum pressure rating that is printed on it. It is a good idea to select a hose with a higher pressure rating than you need so that the hose can handle a spike in pressure.

The hose must also be able to flex and bend without breaking or becoming damaged. This is why you should pay attention to the safety rating, which is usually a 4:1 safety factor. Also consider the length of the hose because the longer the hose is, the more it will increase pressure drop in the system due to head loss caused by friction.