BOP Hose for Drilling Rigs

release date:2023-07-19 09:28:29

reading volume:

share:

BOP Hose for Drilling Rigs

BOP hose is used to control hydraulic functions on drilling rigs. Specifically, these hoses are designed to hold high working pressure in emergency situations such as a well blowout. The BOP equipment that failed on the Deepwater Horizon was a ram-type system with four channels. These systems are supposed to be highly redundant.High Pressure

BOP hoses are designed to handle high pressure and temperature. This is why they have to be made with quality materials to ensure that they can withstand these extreme conditions. The hoses are also designed to remain flexible under these high levels of pressure to make handling easier and prevent the hose from bursting. The BOP stack contains a series of safety valves, including choke line and kill line valves that are used to redirect the mud flow or stop drilling fluid. It can also contain annular or ram-type BOPs that are made of rubber faced steel rams that come together with great force to seal the well bore. Proprietary manufacturers of subsea hose bundle strive to provide products with a low volumetric expansion characteristic (VEC). This helps to maintain API closing times for both annular and ram-type BOPs.High Temperature

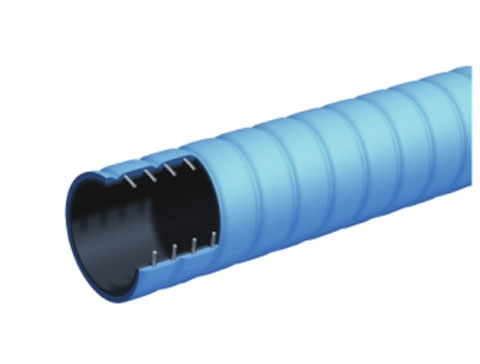

Stainless steel armored type with 1/4" to 2" inside diameter and 5000 psi constant working pressure at ambient temperature. For BOP hose applications that require extreme, erratic pressures and high temperatures that can cause damage or stress to other types of hose, Gates' BLACK GOLD MEGASHIELD is a great choice.

Rated for shear-type rams on deepwater BOPs, this hose can handle high closing forces with the added benefit of fire resistance. It also resists stress cracking, abrasion and chemical attack.

The shear-type rams on deepwater rigs often need more closing force than a standard ram BOP can deliver. In such cases, a booster or auxiliary hydraulic actuator is mounted outside of the main hydraulic actuators to provide additional shearing power for the shear rams. BOP boosters are available in both hydraulic and mechanical versions. Mechanical boosters use threaded shafts to lock rams in place after hydraulic actuation and do not require constant hydraulic pressure. They can be replaced without requiring the removal of the entire BOP assembly.

For BOP hose applications that require extreme, erratic pressures and high temperatures that can cause damage or stress to other types of hose, Gates' BLACK GOLD MEGASHIELD is a great choice.

Rated for shear-type rams on deepwater BOPs, this hose can handle high closing forces with the added benefit of fire resistance. It also resists stress cracking, abrasion and chemical attack.

The shear-type rams on deepwater rigs often need more closing force than a standard ram BOP can deliver. In such cases, a booster or auxiliary hydraulic actuator is mounted outside of the main hydraulic actuators to provide additional shearing power for the shear rams. BOP boosters are available in both hydraulic and mechanical versions. Mechanical boosters use threaded shafts to lock rams in place after hydraulic actuation and do not require constant hydraulic pressure. They can be replaced without requiring the removal of the entire BOP assembly.

Fire Resistance

Blowout prevention systems require high pressure hydraulic control lines that are capable of operating despite tough oil field crisis conditions. These are also designed to hold their rated working pressure even in the face of fire exposure. Our Megashield 5000 BOP hose is an ideal choice for oilfield BOP control applications that must withstand severe and demanding conditions. This flame-resistant hose is capable of maintaining its rated working pressure when exposed to fire for at least five minutes. This hose is made of black oil resistant nitrile tube and a red wrapped finish cover that is both oil and flame-resistant. Its abrasion-resistant construction is reinforced with multiple layers of steel cable and textile fabric. It comes standard with 316SS male threaded ends, but is also available in female NPT and BSPT fittings to accommodate your desired connections. It’s also fitted with crimped couplings that feature over-ferrule fire protection. Finished assemblies are packaged in a heavy-duty corrugated box or wooden crate.Customization

BOPs are complex devices and the subsea deepwater versions have more functions than their direct hydraulic surface counterparts. These additional commands and control pathways have evolved due to both practical considerations, limitations of marine drilling platforms topsides and the capabilities of their riser joints (the mechanical connection between the stack and the drilling installation). Ram BOPs have a vertical well bore and horizontal ram cavity, actuated by threaded ram shafts that translate in the manner of screw jacks. They operate by mechanical advantage, overcome downhole pressures and seal the well. BOP hoses must be capable of operating at high speeds and withstand high impulses. To this end, Verso-LOK swivel lock hose connections restrict loosening by the physics of opposite force and thread jamming. They also withstand fire exposure testing to API 16D and Lloyd’s OD/1000/499 standards. For added protection, they come with stainless steel armor designed to resist abrasion and cutting, gouging and chemical attack.

Previous: