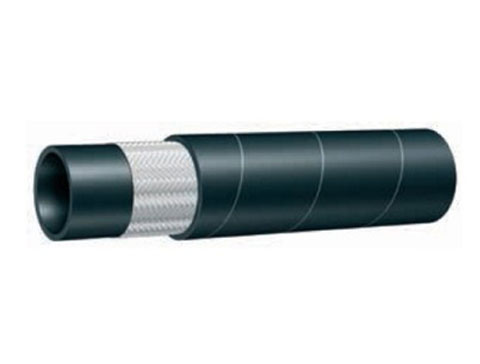

Concrete Pump Hose

release date:2023-07-28 08:31:40

reading volume:

share:

A concrete pump hose is a crucial component of any concrete line pump. They help place concrete efficiently, without wasting materials or creating a mess on the job site. The hose needs to be strong and durable enough to resist damage from the concrete that is being pumped through it. It also needs to be flexible enough to navigate around obstacles and curves.

Flow

Concrete pumping is all about flow. A pump's spec book might say it can produce 50 yd/hr, but the limiting factor is usually the hose. The hose must be the right size to get maximum performance. Several factors influence the yards per hour that a concrete pump can produce, including material cylinder diameter and length, piston face pressure, horse power, and the concrete mix itself. Blockages in a concrete pump line can cause hose blowouts or whipping. The air trapped in the delivery system stores energy that can discharge through the end of the hose and strike workers in the area. The risk of hose-whipping can be reduced by ensuring that no one not involved in the pour is in the "end-hose movement area" at any time. It is also recommended that a ball catcher be fitted to the end of the steel line to prevent concrete from dropping out and catching the wind, which could then propel it across the work site.Durability

Concrete pump hoses are highly durable and can withstand high pressure. Their sturdy construction resists damage from chemicals and corrosion. They also have an easy-to-clean outer covering that protects the hose against abrasion. These hoses are also lightweight, making them easier to transport and use. In addition to being durable, concrete pump hoses are made to be easily cleaned. They are designed with clean-out balls to clear away residue and cement from inside the pipes and hoses. These clean-out balls help reduce the chances of a clog.

It is important to monitor the wear of the hoses to avoid a rupture. This is especially important in a twin-wall pipe. Because the inner surfaces aren’t easily visible, companies typically monitor their hoses by measuring the thickness of the hoses at their ends. They also keep yardage records. These programs help determine when a hose needs to be replaced. Other measures include using a slurry of concrete or oil to prevent the hose from clogging.

In addition to being durable, concrete pump hoses are made to be easily cleaned. They are designed with clean-out balls to clear away residue and cement from inside the pipes and hoses. These clean-out balls help reduce the chances of a clog.

It is important to monitor the wear of the hoses to avoid a rupture. This is especially important in a twin-wall pipe. Because the inner surfaces aren’t easily visible, companies typically monitor their hoses by measuring the thickness of the hoses at their ends. They also keep yardage records. These programs help determine when a hose needs to be replaced. Other measures include using a slurry of concrete or oil to prevent the hose from clogging.