Petroleum Drilling Hose to Meet Your Application

release date:2023-07-19 09:32:52

reading volume:

share:

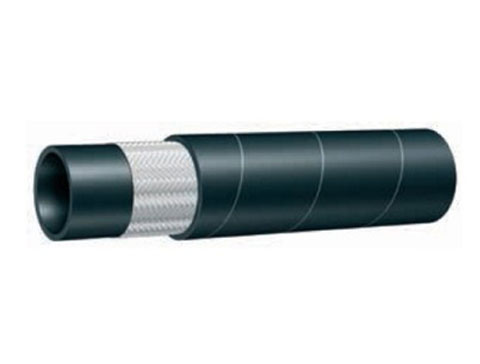

Rotary drilling hoses, also known as kelly hose or mud pump hose, are designed for flexible connection between standpipe and swivel to pump mud at extra high pressure in the oilfield drilling operation and exploration.

High Pressure

Drilling operations operate at a high pressure and temperature, which means that the hoses, fittings and hydraulic components that make up this system must be able to withstand these conditions. If they cannot, the entire operation could be put at risk of catastrophic problems or at least will not work as effectively as it should. Rotary drilling hose (also called oilfield mud hose, kelly hose) is a flexible connection between the standpipe and swivel on the rig to pump mud at extra high pressure in petroleum drilling and exploration. It meets the strict requirements of directional drilling, negative pressure pulse and high temperature downward connections and also can serve as motion compensation hose to stabilize rotary drilling and pumping equipment against vertical wave action on offshore drill platforms. The base is made of an internal rubber layer, then followed by 2-8 layers of high tensile and high strength spiral steel wire, finally covered with a power metal braid. The resulting structure is very resistant to high pressure working conditions.High Temperature

Oil drilling operations often take place in harsh environments where temperatures are extremely high and the pressures fluctuate. The petroleum drilling hoses must be capable of withstanding these extreme temperatures without deteriorating or becoming unusable. In addition, rubber elements on the rig such as seals are susceptible to thermal degradation and require replacement at high rates if they are subjected to excessive heat. It is also important that the petroleum drilling hose can withstand extreme cold conditions as well. These hoses are used for transporting water, mud and other chemicals during the oil exploration process. These hoses are made of a combination of layers, with the internal rubber tube, the power metal braid and the static wire. The hose is resistant to abrasion, oil, mild chemicals, weathering and temperature extremes. It is one of the most critical components on a rig, since it carries vital hydraulic oil that performs a number of functions for the machinery.

It is also important that the petroleum drilling hose can withstand extreme cold conditions as well. These hoses are used for transporting water, mud and other chemicals during the oil exploration process. These hoses are made of a combination of layers, with the internal rubber tube, the power metal braid and the static wire. The hose is resistant to abrasion, oil, mild chemicals, weathering and temperature extremes. It is one of the most critical components on a rig, since it carries vital hydraulic oil that performs a number of functions for the machinery.