In the field of drilling, the kelly hose plays a vital role in facilitating the efficient and safe extraction of resources from the earth's crust. This article explores the significance of a reliable kelly hose and how it enhances drilling efficiency and safety.

Facilitating Efficient Drilling Operations:

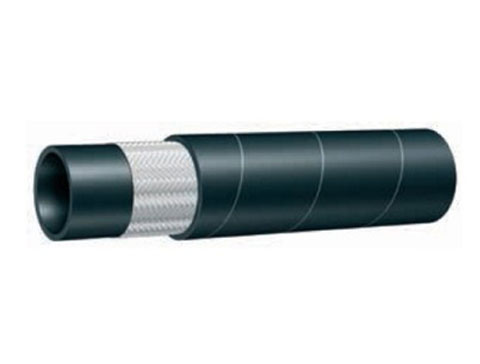

The primary purpose of a kelly hose is to connect the drilling rig to the drill string, allowing for the transfer of drilling fluid and maintaining hydraulic pressure. This facilitates the drilling process by providing a continuous flow of drilling fluid to the drill bit, ensuring efficient penetration and extraction of resources. A well-designed kelly hose minimizes friction loss, pressure drops, and interruptions, optimizing drilling efficiency and reducing operational costs.

Ensuring Safety and Reliability:

Safety is of utmost importance in drilling operations, and a reliable kelly hose plays a crucial role in maintaining a safe working environment. The hose is designed to withstand high pressure, extreme temperatures, and harsh drilling fluids, ensuring its integrity and preventing leaks or ruptures. A sturdy and durable kelly hose reduces the risk of accidents, including blowouts or fluid spills, safeguarding both the personnel and the surrounding environment. It provides operators with the confidence that the drilling process can be carried out reliably and safely.

Handling Challenging Environments:

Drilling operations often take place in challenging environments, such as offshore drilling platforms or remote locations. A kelly hose should be capable of withstanding these demanding conditions. It should be resistant to corrosion, abrasion, and damage from external elements, such as oil, gas, or saltwater. A robust kelly hose can withstand rough handling, extreme weather conditions, and constant movement, ensuring uninterrupted drilling operations and minimizing downtime.

Compliance with Industry Standards:

To ensure drilling efficiency and safety, it is crucial to select a kelly hose that meets industry standards and regulations. These hoses undergo rigorous testing to ensure they can withstand the demanding conditions of drilling operations. Compliance with industry standards ensures that the hose can handle the required pressure, temperature, and environment. It also provides operators with the confidence that the kelly hose is manufactured responsibly, adhering to quality control measures and safety guidelines.

A reliable

kelly hose is an essential component in drilling operations, contributing to both efficiency and safety. By facilitating efficient drilling operations, handling challenging environments, and ensuring compliance with industry standards, a high-quality kelly hose enhances productivity while reducing risks. Operators can rely on a sturdy and well-designed kelly hose for smooth drilling operations, reducing downtime and increasing overall profitability. With the right kelly hose in place, drilling operators can enhance efficiency, safety, and success in their operations.