Enhancing Well Control with a Choke Kill Hose

release date:2023-08-22 15:04:52

reading volume:

share:

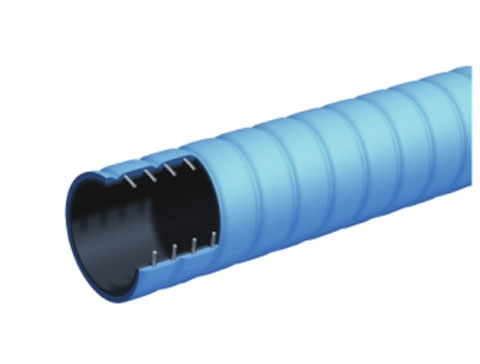

In the realm of oil and gas well control, a choke kill hose plays a pivotal role in maintaining safety and preventing blowouts. This article delves into the significance of a reliable choke kill hose and how it enhances well control in oil and gas operations.

Controlling Fluid Flow and Pressure:

The primary function of a choke kill hose is to control the flow and pressure of fluids during well control operations. When a well experiences a kick or an influx of unwanted fluids, the choke kill hose is utilized to choke back or kill the well, effectively controlling the flow rate and pressure. By effectively managing the fluid dynamics, the choke kill hose ensures that the well remains stable and prevents any potential blowouts.Safeguarding Personnel and Equipment:

Safety is of paramount importance in oil and gas operations, and a dependable choke kill hose plays a crucial role in safeguarding personnel and equipment. The hose is designed to handle high-pressure and high-temperature conditions, ensuring the integrity of the well control system. A robust choke kill hose prevents leaks, ruptures, or other failures, reducing the risk of accidents and protecting the well control operators and equipment from potential harm.