The Versatility of API Rotary Rubber Hose in Oil and Gas Operations

release date:2023-08-22 15:06:22

reading volume:

share:

API rotary rubber hoses are an essential component in the oil and gas industry, providing a flexible and durable solution for transferring drilling mud and other fluids during drilling operations. This article explores the versatility of API rotary rubber hoses and their significant role in ensuring the efficiency and safety of oil and gas operations.

Fundamental Functionality and Construction:

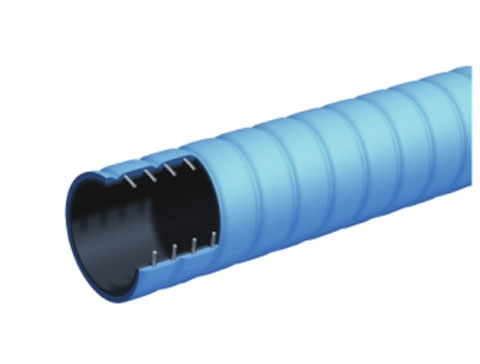

API rotary rubber hoses serve as a vital conduit for the transfer of drilling fluids between the drilling rig and the wellbore. These hoses are constructed with multiple layers of rubber and reinforcement materials, ensuring flexibility, strength, and resistance to high pressure and abrasion. The inner layer is designed to withstand the corrosive nature of drilling mud, while the outer layer protects against external damage. This construction allows the hose to effectively handle the demanding rigors of drilling operations.Adaptability in Various Drilling Environments:

API rotary rubber hoses exhibit a remarkable adaptability to different drilling environments, whether onshore or offshore. These hoses can withstand extreme temperatures, harsh weather conditions, and the constant movement and vibrations associated with drilling activities. They are also designed to resist oil, chemicals, and other fluids encountered during drilling. Their ability to adapt to diverse environments ensures the smooth and uninterrupted transfer of fluids, optimizing drilling efficiency.