Acid and alkali resistant hoses are critical components used in industries where the handling of corrosive chemicals is necessary. These specialized hoses are designed to withstand the harsh effects of acid and alkali exposure, ensuring the safety of operators and preventing damage to equipment. Whether in chemical processing plants, laboratories, or manufacturing facilities, acid and alkali resistant hoses play a crucial role in maintaining a safe and efficient working environment.

Material Composition of Acid and Alkali Resistant Hoses

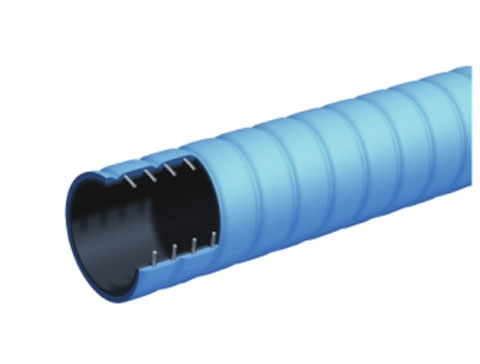

Acid and alkali resistant hoses are typically made from synthetic rubber or thermoplastic materials that offer excellent resistance to corrosive substances. These materials, such as EPDM (ethylene propylene diene monomer) or PTFE (polytetrafluoroethylene), provide superior resistance to chemicals, acids, bases, and solvents. Additionally, acid and alkali resistant hoses may feature reinforced layers, such as textile or metal braids, to enhance their strength and durability.

Applications of Acid and Alkali Resistant Hoses

Acid and alkali resistant hoses find extensive applications in various industries where the handling of corrosive substances is a regular part of operations. In chemical plants, these hoses are used for transferring acids, alkalis, and other corrosive chemicals between storage tanks and processing equipment. In laboratories, acid and alkali resistant hoses are crucial for handling and transferring hazardous materials safely. Additionally, these hoses are utilized in wastewater treatment facilities, metal processing plants, and mining operations.

Advancements in Acid and Alkali Resistant Hose Technology

Technological advancements continue to drive improvements in acid and alkali resistant hose technology, enhancing their performance and reliability. Manufacturers are developing hoses with increased resistance to a wider range of corrosive substances, ensuring compatibility with various chemicals used in different industries. Additionally, improvements in hose construction and reinforcement techniques enhance their durability and longevity. These advancements in acid and alkali resistant hose technology result in safer operations, reduced downtime, and increased productivity.

In conclusion, acid and alkali resistant hoses are vital components in industries that handle corrosive substances. With their ability to withstand the harsh effects of acids, alkalis, and other corrosive chemicals, these hoses ensure the safety of operators and the integrity of equipment. Ongoing advancements in acid and alkali resistant hose technology continue to improve their resistance capabilities, expanding their range of applications and providing enhanced performance and reliability. By choosing the right acid and alkali resistant hoses, industries can maintain a safe and efficient working environment while handling corrosive substances effectively.