Flexible hoses and mud pipes: essential tools in construction projects

release date:2024-07-30 10:47:38

reading volume:

share:

In modern construction projects, mining, oil exploration and many other industrial fields, flexible hoses and mud pipes play an indispensable role as important conveying media. They can not only effectively convey liquids, gases and muds, but also provide superior solutions for applications under various working conditions due to their unique design and material properties. This article will discuss in detail the types, characteristics, application areas and matters that need to be paid attention to when purchasing and using flexible hoses and mud pipes, and comprehensively analyze the advantages and influence of these two key pipes.

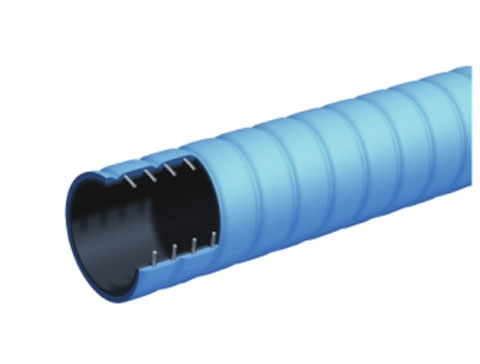

1. Overview of flexible hoses

Flexible hoses are a kind of soft pipe made of a variety of materials, usually used to convey liquids or gases. It can be customized with different raw materials, structures and sizes according to different working conditions. The design of flexible hoses makes them flexible and bendable, and can adapt to a variety of complex environmental requirements. 1.1 Main features The main features of flexible hoses include: - Pressure resistance: able to withstand high working pressure to ensure safe transportation. - Temperature resistance: It has good high and low temperature performance and can adapt to various temperature environments according to different materials. - Flexibility: It can be bent freely in a small space, which is convenient for installation and use. - Corrosion resistance: According to the selection of different materials, it can resist the corrosion of various chemical media.2. Overview of mud pipes

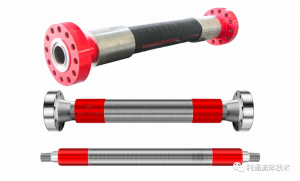

Mud pipes are mainly used to transport mud, fluids and other industrial media, and are widely used in drilling, exploration and construction. Due to the particularity of mud liquid, mud pipes need to have stronger wear resistance and pressure resistance. 2.1 Special performance The special properties of mud pipes include: - Strong wear resistance: Since the mud contains solid particles, the mud pipe needs to have excellent wear resistance. - High pressure bearing capacity: The specially designed pipe wall thickness and structure can effectively withstand the impact of high-pressure fluids. - Anti-bending performance: During construction, mud pipes need flexibility so that they can be used in intense construction environments.

- Anti-bending performance: During construction, mud pipes need flexibility so that they can be used in intense construction environments.