In modern industry and engineering machinery, high-pressure hoses, as an important part of the hydraulic transmission system, play a pivotal role. Among them, armored high-pressure hoses are increasingly favored by various users due to their excellent performance, oil resistance and excellent pulse performance. In this article, we will discuss in detail the advantages of armored high-pressure hoses and their performance in various application scenarios to help you understand their characteristics more deeply and choose the product that suits you best.

Core advantages of armored high-pressure hoses

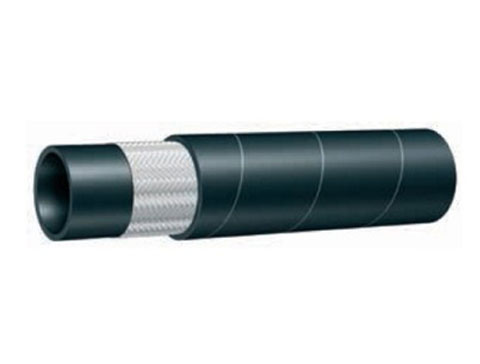

Armored high-pressure hoses are mainly composed of inner rubber layer, middle rubber layer, steel wire braided layer and outer rubber layer. The inner rubber layer is made of highly oil-resistant synthetic rubber material, which can remain stable under high temperature and high pressure environments, and is not easily corroded by hydraulic oil, lubricating oil and other oil substances, ensuring the reliability and safety of long-term use. Whether it is mining machinery, petroleum equipment or engineering vehicles, it can adapt to various harsh working conditions to the greatest extent.

Superior pulse performance

Pulse performance is one of the important indicators for measuring hydraulic oil pipes. Excellent pulse performance means that hydraulic pipes can withstand high-frequency and high-amplitude pressure changes, effectively extending their service life. The armored high-pressure hose adopts a multi-layer steel wire braided structure, which can disperse pressure shocks, reduce stress concentration, and reduce the troubles caused by pulses, so that it performs particularly well under complex working conditions.

Anti-twisting and wear resistance

The working environment of industrial machinery and hydraulic equipment is complex and changeable, and high-pressure hoses often need to serve in bending, stretching, and torsion. Therefore, wear resistance and anti-twisting performance are also important criteria for measuring the quality of a high-pressure hose. The outer rubber layer of the armored high-pressure hose also uses synthetic rubber with high wear resistance, supplemented by the steel wire armor layer, so that it can still maintain a good use state in mechanical friction and high-frequency bending movements, greatly improving its service life.

High pressure resistance and safety

The armored high-pressure hose has a high design pressure, which can meet the high-pressure requirements of various harsh working conditions and ensure the safety and stability of the hydraulic system. During the production process, each high-pressure hose will undergo rigorous pressure testing and quality inspection to ensure that it can perform reliably under extreme working conditions and avoid equipment failures and safety accidents caused by hose rupture or leakage.

Widely used and adaptable to various working conditions

Engineering machinery

In the field of engineering machinery, such as excavators, bulldozers, concrete pump trucks, etc., the hydraulic system is the core component of its power system. The armored high-pressure hose, as a key component of hydraulic oil delivery, bears huge pressure and high-frequency pulse transmission. Therefore, the armored high-pressure hose with excellent performance has a wide range of applications in this field, which not only ensures the smooth operation of the hydraulic system, but also greatly extends the maintenance cycle of the equipment and reduces maintenance costs.

Petrochemical

The petrochemical industry has extremely stringent requirements for oil resistance, high temperature resistance, and high pressure performance. Armored high-pressure hoses are widely used in oil drilling equipment, oil refining equipment, and various chemical equipment with their excellent technical performance. It can not only withstand complex and harsh working conditions, but more importantly, it has excellent corrosion resistance and mechanical strength to ensure the safety and stability of equipment operation.

Mining machinery

Mining machinery, such as mine hoisting equipment, coal mining machines, and tunneling machines, has a harsh and dusty working environment, and requires extremely high durability of the equipment. High-quality armored high-pressure hoses have good wear resistance and high tensile strength, and can operate efficiently for a long time in the harsh environment of mining machinery. Moreover, their explosion-proof performance also provides a solid guarantee for the safety of the equipment.

Agricultural machinery

With the improvement of automation in modern agricultural machinery, hydraulic systems are increasingly used in agricultural machinery. The application of armored high-pressure hoses in tractors, combine harvesters, plant protection machinery and other equipment enables them to handle more complex field operations and improve the efficiency and output of agricultural production. Its excellent aging and corrosion resistance can effectively resist the erosion of agricultural chemicals and adapt to a variety of farmland environments.

Important role in industrial manufacturing

In the field of industrial manufacturing, high-pressure hoses also play an important role. Whether it is the hydraulic system of CNC machine tools or various industrial automation equipment, armored high-pressure hoses play a key transmission role in them. By choosing high-quality armored high-pressure hoses, the overall performance and stability of manufacturing equipment can be improved, the production line can be ensured to operate efficiently, and higher production benefits can be brought to the enterprise.

Manufacturer wholesale, quality assurance

Choosing a suitable armored high-pressure hose manufacturer is a prerequisite for ensuring product quality and performance. In professional manufacturers, these high-pressure hose products usually pass ISO9001 and other international quality management system certifications, and have advanced production equipment and perfect testing methods. Wholesale purchases can not only get preferential prices, but also enjoy professional technical support and after-sales service to ensure timely maintenance and repair of products during use.

Professional armored high-pressure hose manufacturers will provide customized product solutions according to the needs of different customers, including personalized customization services such as pipe diameter, length, and joint form, to meet the diverse needs of customers to the greatest extent.

Armored high-pressure hoses have become an indispensable key component in the fields of industry, agriculture, petrochemicals, mining machinery, etc. with their excellent oil resistance, excellent pulse performance, excellent anti-twisting and wear resistance. Choosing professional manufacturers for wholesale not only ensures the high quality and stability of the products, but also enjoys more cost-effective customized services, effectively improves the operating efficiency of equipment, and reduces maintenance costs.

I hope that through this detailed introduction, you will have a better understanding of the various superior performances and wide applications of armored high-pressure hoses, choose the high-quality products that best suit your needs, and achieve more project success and efficiency improvement.

Superior pulse performance

Pulse performance is one of the important indicators for measuring hydraulic oil pipes. Excellent pulse performance means that hydraulic pipes can withstand high-frequency and high-amplitude pressure changes, effectively extending their service life. The armored high-pressure hose adopts a multi-layer steel wire braided structure, which can disperse pressure shocks, reduce stress concentration, and reduce the troubles caused by pulses, so that it performs particularly well under complex working conditions.

Anti-twisting and wear resistance

The working environment of industrial machinery and hydraulic equipment is complex and changeable, and high-pressure hoses often need to serve in bending, stretching, and torsion. Therefore, wear resistance and anti-twisting performance are also important criteria for measuring the quality of a high-pressure hose. The outer rubber layer of the armored high-pressure hose also uses synthetic rubber with high wear resistance, supplemented by the steel wire armor layer, so that it can still maintain a good use state in mechanical friction and high-frequency bending movements, greatly improving its service life.

High pressure resistance and safety

The armored high-pressure hose has a high design pressure, which can meet the high-pressure requirements of various harsh working conditions and ensure the safety and stability of the hydraulic system. During the production process, each high-pressure hose will undergo rigorous pressure testing and quality inspection to ensure that it can perform reliably under extreme working conditions and avoid equipment failures and safety accidents caused by hose rupture or leakage.

Widely used and adaptable to various working conditions

Engineering machinery

In the field of engineering machinery, such as excavators, bulldozers, concrete pump trucks, etc., the hydraulic system is the core component of its power system. The armored high-pressure hose, as a key component of hydraulic oil delivery, bears huge pressure and high-frequency pulse transmission. Therefore, the armored high-pressure hose with excellent performance has a wide range of applications in this field, which not only ensures the smooth operation of the hydraulic system, but also greatly extends the maintenance cycle of the equipment and reduces maintenance costs.

Petrochemical

The petrochemical industry has extremely stringent requirements for oil resistance, high temperature resistance, and high pressure performance. Armored high-pressure hoses are widely used in oil drilling equipment, oil refining equipment, and various chemical equipment with their excellent technical performance. It can not only withstand complex and harsh working conditions, but more importantly, it has excellent corrosion resistance and mechanical strength to ensure the safety and stability of equipment operation.

Mining machinery

Mining machinery, such as mine hoisting equipment, coal mining machines, and tunneling machines, has a harsh and dusty working environment, and requires extremely high durability of the equipment. High-quality armored high-pressure hoses have good wear resistance and high tensile strength, and can operate efficiently for a long time in the harsh environment of mining machinery. Moreover, their explosion-proof performance also provides a solid guarantee for the safety of the equipment.

Agricultural machinery

With the improvement of automation in modern agricultural machinery, hydraulic systems are increasingly used in agricultural machinery. The application of armored high-pressure hoses in tractors, combine harvesters, plant protection machinery and other equipment enables them to handle more complex field operations and improve the efficiency and output of agricultural production. Its excellent aging and corrosion resistance can effectively resist the erosion of agricultural chemicals and adapt to a variety of farmland environments.

Important role in industrial manufacturing

In the field of industrial manufacturing, high-pressure hoses also play an important role. Whether it is the hydraulic system of CNC machine tools or various industrial automation equipment, armored high-pressure hoses play a key transmission role in them. By choosing high-quality armored high-pressure hoses, the overall performance and stability of manufacturing equipment can be improved, the production line can be ensured to operate efficiently, and higher production benefits can be brought to the enterprise.

Manufacturer wholesale, quality assurance

Choosing a suitable armored high-pressure hose manufacturer is a prerequisite for ensuring product quality and performance. In professional manufacturers, these high-pressure hose products usually pass ISO9001 and other international quality management system certifications, and have advanced production equipment and perfect testing methods. Wholesale purchases can not only get preferential prices, but also enjoy professional technical support and after-sales service to ensure timely maintenance and repair of products during use.

Professional armored high-pressure hose manufacturers will provide customized product solutions according to the needs of different customers, including personalized customization services such as pipe diameter, length, and joint form, to meet the diverse needs of customers to the greatest extent.

Armored high-pressure hoses have become an indispensable key component in the fields of industry, agriculture, petrochemicals, mining machinery, etc. with their excellent oil resistance, excellent pulse performance, excellent anti-twisting and wear resistance. Choosing professional manufacturers for wholesale not only ensures the high quality and stability of the products, but also enjoys more cost-effective customized services, effectively improves the operating efficiency of equipment, and reduces maintenance costs.

I hope that through this detailed introduction, you will have a better understanding of the various superior performances and wide applications of armored high-pressure hoses, choose the high-quality products that best suit your needs, and achieve more project success and efficiency improvement.