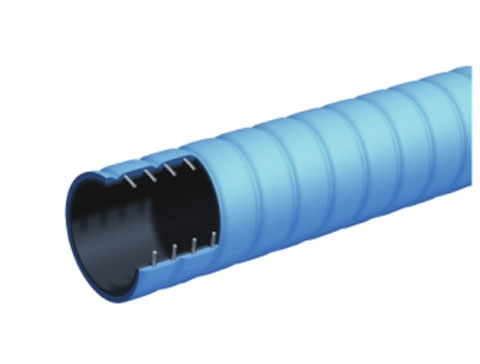

On April 20, most of the members of Litong Business School are the backbone of various departments of Litong, and take up the leadership and management positions of the unit. Members of the Leetong Business School gathered this morning for an "autonomy" training session. The purpose of the training is to convey an important message to all members that if you want to effectively control others, you must first assert yourself, and there are four aspects to strict leadership of yourself. The first practice: "I have three provinces and my body"; The second practice: You have self-knowledge; The third practice: Pain because of belief; The fourth practice: To achieve the mentality of wisdom. 7K standard water hose, commonly known as drilling hose, common accessories include crimping sleeve (iron sheet), crimping transfer (steel core), hammer union of specified size, the type of joint is generally confirmed at the beginning of the order, by The company's special department conducts design or procurement. After the tube body is tested, the assembly seizure department will carry out the seizure operation. Each faucet is produced from the factory, and a special pressure test and joint test will be done to ensure that there will be no quality problems during the use of the product. As a strategic industry, the oil and natural gas industry plays an irreplaceable role in ensuring my country's energy security. In recent years, in order to encourage the development of oil and natural gas drilling and production industries, my country has successively issued a series of incentive policies. From 2019 to 2020, the National Energy Administration has issued relevant industry promotion policies and held several working conferences related to enhancing oil and gas exploration and development efforts, emphasizing the enhancement of domestic oil and gas security capabilities, and promoting large oil companies such as PetroChina, Sinopec, and CNOOC. Implement the "Seven-Year Action Plan". API 16C Series - Choke and Kill Hose can be used for flexible connections between risers and manifolds. The installation deviation of the drilling rig can be adjusted. It has the characteristics of high pressure resistance, fire resistance, heat insulation and flame retardant. Comply with API Spec 16C. According to different uses, it is divided into two categories: one is the blowout preventer (BOP) hydraulic control line. The other is the flexible choke and kill pipeline, which can well meet the needs of customers.The frosted UPE film is made of high-quality raw materials, with a minimum molecular weight of 840, which meets ISO requirements. According to customer requirements, it can be made into any thickness of 0.0.08-3mm. At the same time, because of its low density, light weight, good stability and long service life, it is more wear-resistant than traditional Teflon, and its high temperature resistance is only It is inferior to Teflon material, so it is the first choice material that can gradually replace Teflon. Abrasion-resistant sandblasting and abrasive hoses rely on the integrity of the hose to tell if a hose needs to be replaced: one way to identify a hose is to squeeze it. The sandblasting hose should be squeezed every 20 cm in length, a suitable hose is difficult to squeeze, if the hose is pressed down when squeezed, it indicates that the inner wall is corroded due to the flow of abrasive and should be replaced. If only one spot is dented, and it's near one of the ends, you can cut off the worn part and attach the fitting to the end.More about - wear-resistant sandblasting and frosted hoses will be updated gradually, so stay tuned. Tags you may be concerned about: Scrub sandblasting wear-resistant hose Related tags Article Quantity: Frosted (5) Sandblasted (75)