Air hoses consist of flexible tubes that are designed to transport compressed air from an compressor to an air tool. They are typically made of a durable material that can handle high air pressures.

Most hoses come pre-fitted with a type of fitting that can connect easily to air compressor tools and other equipment. The fittings usually have a barbed profile and are marked with a fractional size that matches the hose.

How to choose an air hose

Choosing the correct length of air hose is an important consideration. You want a hose that is long enough to enable you to work comfortably without restricting your movements or getting in the way of other users. The right length will reduce the risk of pressure drop as air travels through a hose.

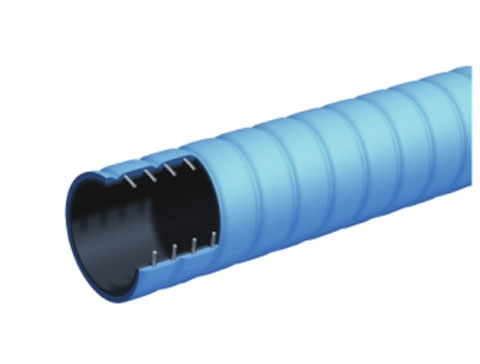

Another thing to consider is the material of the hose. The material used to construct a hose can affect its weight, flexibility and performance. PVC is the most common material. It has a proven track record for durability, abrasion resistant and chemical compatibility. Other materials include nylon and neoprene rubber. Nylon is lightweight, easy to transport, and cost-effective for most home applications. Neoprene is thicker, heavier and more dependable than nylon. It is resistant to abrasion, oil and weathering, and can be used with permanent or reusable connections.

Another thing to keep in mind is that the internal diameter (ID) of an air hose varies much less than its external diameter, and this can be confusing. For example, one hose might have an ID of 3/8'' and another might be 1 1/4'', but both may have the same outer diameter. It's therefore essential to know the ID of your air hose before purchasing one.

Air hose fittings

Air hose fittings are a critical component to your air compressor system. They allow you to connect and disconnect air tools quickly without losing internal pressure. They also seal to prevent leaks and provide flexibility for use. They are available in a wide range of materials from lightweight plastics, to traditional rubber or neoprene. Regardless of the type, they are usually made up of two parts - a coupler and a connector. These connections are easily misplaced or damaged, so it is important to keep a spare on hand. This will ensure that you never run out of air and can continue working.

The standard National Pipe Thread (NPT), is the most common type of air hose fitting. This fitting has a male NPT plug and a female coupler. Many air hoses come with both NPT and quick-disconnect fittings.

The most common size for air hoses is a quarter-inch. This is a good size for most applications, but you should check the specs on your pneumatic tools to make sure the fittings will be compatible. Some companies have multiple crews, so it may be helpful to have different colors and styles of air hoses so that the teams don't accidentally use each other's hoses. Air hose fittings come in many styles, ranging from automotive to industrial.

Production standards for air hose

Air hoses are used to convey gases and air over long distances in various applications. They are made from a variety of materials, sizes, and designs to meet specific needs. They can also offer a range of other features, including flexibility, durability, and resistance to heat, chemicals, and abrasion.

There are several different standards for air hoses and gas hoses. Most of these are based on the requirements for the materials and working pressures of the hoses. The hoses must be tested to ensure they meet the specifications. Usually, they are certified by an independent testing laboratory. Customers, manufacturers, suppliers, and testers can all access the test results.

The fittings of an air hose is essential for the proper operation of the hose. They must be capable of withstanding the required working pressure and any surges or peak pressures. These fittings are usually made of brass or type 304/316 Stainless Steel, and must be resistant to abrasion and corrosive gases or air flowing through the hose.

Standard (straight) air hoses are typically fitted in retractable reels operated by a crank handle. They are often a good choice for hand-operated tools because they allow you to move freely and can be stored easily. Coiled air hoses are heavier and take up more space.