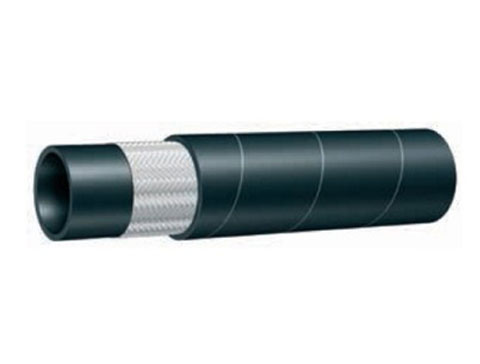

Fuel Hose Pipe

release date:2023-06-30 10:42:49

reading volume:

share:

Fuel hose pipe transports gasoline, fuel oils and vapors in gaseous environments. It is available with various types of couplings and clamps, including worm drive or band clamps and special AN fittings. The fuel line may become blocked by kinks in the metal pipes or by rubber connectors. Blocked fuel lines will deteriorate inside, causing internal leaks that can cause serious harm.

Strength

Fuel hose is used for the conveyance of flammable substances such as diesel, oil, and other petroleum products. It is extremely strong and can handle high-pressure levels, making it a great choice for vehicles. This hose is also resistant to abrasion, corrosion and fire. It is available in various lengths and diameters. There are several types of fuel hose available on the market, and each type has different characteristics. Some have better resistance to oxidized fuel, while others are more permeable. You should read the SAE rating displayed on the hose to determine what it is suitable for. Nitrile fuel hose is made from a chemically bonded, three-layer process. The inner layer is composed of a nitrile rubber compound. This is then surrounded by an outer cover that is made of a high-quality synthetic rubber. The inner and outer layers are then fused together using heat and pressure. The hose is then wrapped with a layer of heat-resistant fiber that is intimately attached to the two-ply rubber tube.Corrosion

Petrol hose pipe is used to transfer petrol and other petroleum products in liquid environments. It is used in cars and many other types of motorised vehicles, as well as industrial applications. It is available in different material markups and sizes to suit a variety of situations. The corrosion of steel pipes can lead to leaking or blockages. This is usually caused by galvanic action, where metals of lower value in the galvanic series corrode and attack other higher value metals. The rate of corrosion is influenced by a number of factors, including the water's acidity, temperature, and soil type. Soils with high sand content tend to have reduced corrosion rates than clay-based soils. A blocked fuel line is a serious problem, since it can prevent the car running. A blocked fuel line may also cause the carburettor to overheat and stop working. Checking the fuel pipe for a blockage is straightforward, but care should be taken to not inhale petrol vapors or fumes.