Choosing the Right Concrete Pump Rubber

release date:2023-07-28 08:35:22

reading volume:

share:

Concrete pumps save time, money, and energy during construction projects. These specialized machines work fast and efficiently to pour concrete accurately. Boom pumps are ideal for large-scale industrial projects and high-rise buildings while small line pumps work well on backyard patios and shed foundations or to lay slabs for swimming pools. But a concrete pump hose must be able to handle extreme concrete pressure.

Types

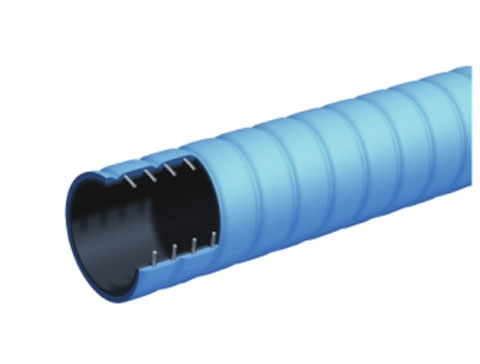

There are many different types of concrete pumps available, each designed for specific building projects. Choosing the right one can save time and money while simplifying building construction. Generally speaking, there are two basic types of concrete pump rubber: steel wire-reinforced and fabric-reinforced. Each type is used to transport concrete from the machine to the pouring location. A truck-mounted boom concrete pump is a high-pressure pump that mounts on a truck and includes an articulating robotic arm, also known as a boom, that can be remote-controlled to precisely distribute concrete at the construction site. The boom can move up, down, and around tight spaces and obstacles to place concrete where needed. A trailer concrete pump, on the other hand, sits on a trailer and is attached to a hose that can reach far away sites. These pumps are ideal for pouring concrete on building projects that require a lot of work in an area with limited space and many impediments.Applications

Concrete pumps can be used for a variety of construction projects to save time and money. They are more efficient than wheelbarrows and allow contractors to place concrete quickly and accurately. Concrete pumping also requires fewer people to operate the equipment, which makes it easier for projects to stay on schedule and within budget. The two primary types of concrete pumps are line pumps and boom pumps. A line pump consists of a trailer-mounted hose system that a truck tows to the job site. A boom pump reaches over, under, or far away from the concrete mixer truck, making it ideal for high-rise construction and tunneling work.

Before pouring concrete, the pump hose should be primed with slurry to prevent it from blocking up during the process. It is also essential that the right type of concrete mix is used for a project, as other mixes can block the line or cause hose whip. This violent phenomenon occurs when air is trapped in the delivery hose and can result in serious injuries.

The two primary types of concrete pumps are line pumps and boom pumps. A line pump consists of a trailer-mounted hose system that a truck tows to the job site. A boom pump reaches over, under, or far away from the concrete mixer truck, making it ideal for high-rise construction and tunneling work.

Before pouring concrete, the pump hose should be primed with slurry to prevent it from blocking up during the process. It is also essential that the right type of concrete mix is used for a project, as other mixes can block the line or cause hose whip. This violent phenomenon occurs when air is trapped in the delivery hose and can result in serious injuries.