Demolition Tool Hose

release date:2023-07-28 08:50:55

reading volume:

share:

Whether you’re gutting an old bathroom or demolishing an entire home, you need a few good demolition tools. This includes a demolition hammer, which is a heavy-duty power application tool that uses a percussive action to tear down structures. Many demolition contractors choose an automatic quick coupler for their carrier so they can switch attachments more quickly, rather than getting off their machine and on the ground to change a shear or pulverizer.

Hydraulic Hoses

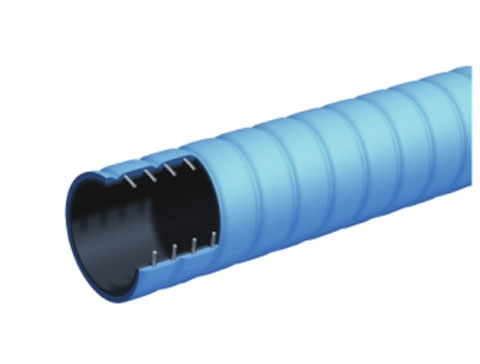

Hydraulic hoses must meet stringent standards to adapt to the high levels of pressure, loads and sometimes contorted positions that they encounter. They are used in demolition, mining and construction, oil industries, transportation equipment like excavators and backhoes, lifting equipment like jacks and more. They are designed to transport liquid hydraulic fluids. They have a three-layer general construction that includes an inner tube, reinforcement and cover. The inner tube is often made from PDFE, thermoplastic or synthetic rubbers that are compatible with the liquid it carries. The reinforcement is a coiled or braided wire set that supports the tubing and protects it from tears. The outer cover is made from rigid materials to protect the innards from abrasion, chemicals and weather. Field-attachable couplings can be screw-together or clamp-type. A screw-together coupling attaches to the hose with an insert that screws into the shell and a clamp-type coupling has a two or four bolts and nuts that clamp onto the hose OD.

Field-attachable couplings can be screw-together or clamp-type. A screw-together coupling attaches to the hose with an insert that screws into the shell and a clamp-type coupling has a two or four bolts and nuts that clamp onto the hose OD.