PTFE Convoluted Hose

release date:2023-07-28 08:58:12

reading volume:

share:

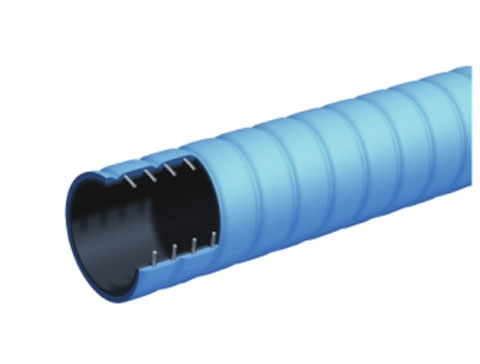

A hose is a tubing used to convey liquids and, in some cases, gases from one location to another. People use them in a variety of settings, from gardening to putting out fires. Convoluted PTFE hoses offer greater flexibility than smooth bore PTFE lining and have a lower minimum bend radius. They also have superior flex fatigue life and are kink-resistant.

PTFE

Convoluted PTFE hoses use patterned depressions in the PTFE inner liner to allow for tighter bend radius without kinking and provide superior flex fatigue life. These hoses are ideal problem solvers for fluid transfer applications involving aggressive chemicals, extreme temperatures/pressure or extreme movement & vibration. The PTFE lining is virtually inert to all chemicals and solvents (except fuming Sulphuric and Nitric Acids, Antioxidants and Methanol), has good radiation resistance and can withstand extremely high temperatures without damage or degradation. Conductive PTFE hoses have a black static-dissipative inner liner that allows electrical charge to dissipate through the hose, reducing the risk of fire and explosion. These hoses are often used in fuel lines running methanol, ethanol, or leaded gasoline to eliminate the danger of methanol vapor permeation that can corrode aluminum fittings and hoses.Stainless Steel Wire Reinforced

Stainless steel wire reinforcement is found in many industrial hoses that have a high-pressure rating. The hose’s ability to resist pressure is dependent on the corrugated stainless-steel core and the stainless-steel braid working together. The corrugated stainless-steel core grants great hoop strength, while the tensile strength of the braid prevents the core from elongating. The stainless-steel braid offers great resistance to abrasion and chemicals that are detrimental to standard delivery hoses. Brookfield Wire supplies stainless-steel wire that can be used in the manufacturing of metal hoses for applications that demand abrasion resistance and longevity.

The stainless-steel braid offers great resistance to abrasion and chemicals that are detrimental to standard delivery hoses. Brookfield Wire supplies stainless-steel wire that can be used in the manufacturing of metal hoses for applications that demand abrasion resistance and longevity.