Blowout Preventer Oil Drilling Hose

release date:2023-08-14 09:49:49

reading volume:

share:

The Blowout Preventer (BOP) on a drilling rig is a large device that works to shut down an oil well in case the crew loses control of the formation fluids. It is important for the safety of the crew and natural environment that this device function properly. Ensure the pipe rams of each BOP have shearing and sealing pressures appropriate to its intended operation. Include this verification with your APD and APM submittals.

Hydraulic Control Line Hose

Preventive maintenance can keep your hydraulic system healthy and improve your equipment’s performance. By regularly inspecting and repairing your hydraulic hose, you can avoid machine failure that can lead to injuries. This also helps you comply with compliance standards and ensure your team’s safety at work. It is important to know the working pressure and temperature rating of your hydraulic hose. Operating above or below the hose’s rated temperature can reduce its life and cause damage. Customers are asking for products that can withstand higher temperatures. This is because design advancements are making equipment smaller, causing air to circulate in small compartments. This can cause the hydraulic hose to heat up and become less flexible. To mitigate these risks, make sure to choose a high-quality product that has a good hose temperature rating and can handle high pressures. Our PRO Mode feature allows you to store your favorite crimp specs so you can skip the steps and go straight to selecting the right size.Fire Resistant Cover Hose

Fire sleeve is the perfect solution for hoses that need to handle high heat and occasional flame. It is made from braided fiberglass yarns in a flexible substrate that’s coated with thick iron oxide red silicone rubber. It protects hoses, cables and wires from burn injuries and can be installed over them easily without disconnecting or removing the items. It’s self-extinguishing and can be used in plenum spaces and above a drop ceiling. It’s resistant to molten metal splash, radiant heat, abrasion, chemicals, corrosive atmosphere and moisture. It can also prevent the media from overheating during use and helps to reduce friction between the hose and nozzle. It’s available in a range of sizes and features an optimised mechanical fitting that contributes to better usability. It’s also highly compatible with existing hoses. It can also be included in a pre-assembled kit or subassembly to save time and effort when installing it. It is also available in multiple lengths to suit your application requirements.

It’s resistant to molten metal splash, radiant heat, abrasion, chemicals, corrosive atmosphere and moisture. It can also prevent the media from overheating during use and helps to reduce friction between the hose and nozzle. It’s available in a range of sizes and features an optimised mechanical fitting that contributes to better usability. It’s also highly compatible with existing hoses. It can also be included in a pre-assembled kit or subassembly to save time and effort when installing it. It is also available in multiple lengths to suit your application requirements.

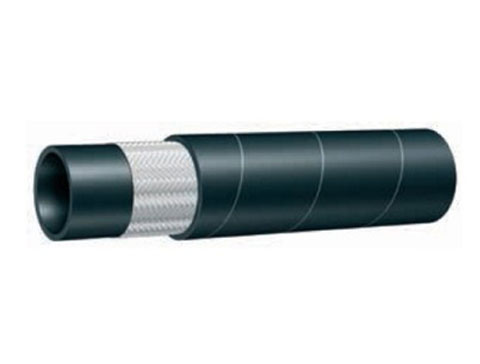

Blowout Preventer Control Line Hose

Blowout Preventer (BOP) control hoses are manufactured with superior components to operate under tough crisis oilfield conditions and maintain their full rated working pressure. They are tested to API 16D standards and capable of withstanding flame temperatures up to 1300degF for five minutes. BOPs are a series of safety valves stacked together that seal the well in case of an unexpected blowout, a disastrous event that can cause irreparable damage to the drill rig, the natural environment and the oil and gas reservoir. For this reason, BOPs are extremely important and must be able to do their job in the worst of circumstances.Subsea Control Line Hose

BOP control line hose is designed to withstand seawater and can range in length from a few feet to hundreds of feet. These hoses can carry power and communication signals between the topside of the rig and the subsea equipment. The hoses extend down to a vertical support that is often located on the seafloor and connected to the subsea equipment. The control lines may also connect multiple pods on the BOP stack and can be selectively actuated by means of a pod selector four-way valve that has one position that supplies fluid power to a corresponding pod control line while the other position vents off the pod selector power supply line to a corresponding pod control line. Proprietary manufacturers of these hoses strive to design and manufacture them with a low volumetric expansion characteristic (VEC) to allow for faster response times when activating subsea pod valves on the BOP stack. This allows the API closing times to be met for ram and annular type blowout preventers.

Previous: