Choke Kill Hose and the Global Choke and Kill Manifold Market

release date:2023-08-14 09:52:41

reading volume:

share:

In the oil industry, choke kill hoses are essential equipment that help to control pressure during drilling. These are connected to the BOP stack and allow heavy drilling mud to be directed into a well to prevent a blowout. A hose is a flexible tubing that is used to transport fluids. There are several factors that affect the design of a hose, including its pressure rating and weight.

What is Choke Kill Hose?

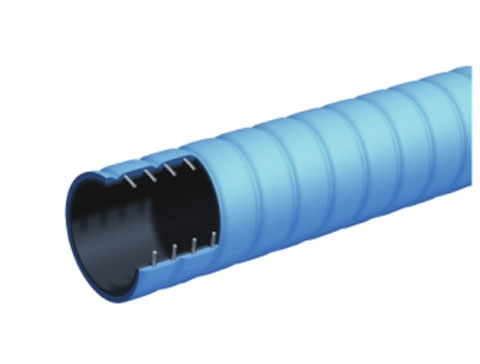

Choke Kill hose is a flexible connection below the blowout preventer assembly, which transfers well fluids to the choke manifold during oil drilling and exploration. It can withstand high pressures and flows of well control operations. It features stainless steel stripwound cover, which isolates the rubber from mechanical damage, cuts, ozone and oils. This ensures that it can withstand sudden high pressure, which helps to reduce downtime, accidents and other losses. The hoses also feature integral connections that resist pull-off during pressure tests. This increases the safety and reliability of the hoses. Tube: Modified nitrile, black. Resists abrasion, corrosion, oil and up to 20% H2S.Applications of Choke Kill Hose

Choke and kill manifolds are necessary pieces of oilfield equipment for preventing well kick and pressure fluctuations during drilling. The rising demand for energy has increased the need for these types of equipment, which has led to a rise in the overall choke and kill manifold market. Chokes are often used to control the flow of fluids, including mud, in a well. They also can be used to transfer well fluids from one part of a rig to another. Typically, chokes are made from steel and have a high-pressure rating.

Choke lines are also used as a flexible connection for locations when a drill platform or semi-submersible drilling vessel moves relatively and the installation dimensions of the drill rig subsequently change. They are also used to transfer oil, gas, mud and other high-pressure media. They are available with a variety of options, such as electric heat tracing and stainless-steel armored covers. They can be provided with a variety of couplings, such as hammer unions, flanged connections and clamp connections.

Chokes are often used to control the flow of fluids, including mud, in a well. They also can be used to transfer well fluids from one part of a rig to another. Typically, chokes are made from steel and have a high-pressure rating.

Choke lines are also used as a flexible connection for locations when a drill platform or semi-submersible drilling vessel moves relatively and the installation dimensions of the drill rig subsequently change. They are also used to transfer oil, gas, mud and other high-pressure media. They are available with a variety of options, such as electric heat tracing and stainless-steel armored covers. They can be provided with a variety of couplings, such as hammer unions, flanged connections and clamp connections.

Suppliers of Choke Kill Hose

Choke and kill hoses are designed to withstand the high pressure conditions of oil field operations. They are typically rated for working pressures of several thousand to tens of thousands of pounds per square inch (psi). The material used in the construction of choke and kill hoses is often highly abrasion-resistant and has a high level of corrosion resistance. These properties are necessary in order to prevent the hose from being damaged during use. Choke and kill hoses are usually equipped with specific end connections that allow them to be connected to other equipment on the oil field. These connections are typically threaded or flanged, and they provide a secure and leak-resistant connection. Choke and kill hoses are also available with stainless steel stripwound covers that isolate the rubber cover from mechanical damage, cuts, abrasion, oil, ozone, and fire. They can also be welded or with an integral union and have an API spec 16C and SY/T5323-2004 approval.

Previous: