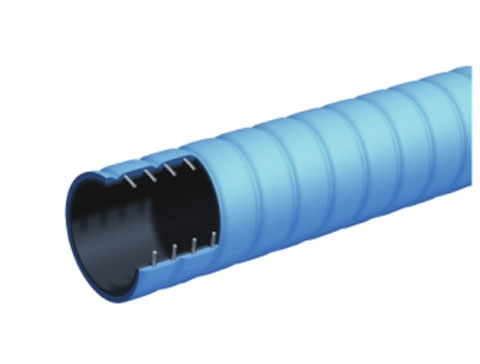

Woven hoses are versatile and durable components that find extensive applications in various industries. These hoses are constructed using a weaving technique, which imparts a unique set of characteristics, making them suitable for a wide range of applications. From handling fluids and gases to conveying powders and granules, woven hoses play a vital role in ensuring efficient and reliable operations in industries such as agriculture, construction, mining, and manufacturing.

Flexibility and Adaptability of Woven Hoses

One of the key advantages of woven hoses is their exceptional flexibility. The weaving technique used in their construction allows for the incorporation of braided or spiraled reinforcement, providing the necessary strength and flexibility. This flexibility enables easy maneuverability around obstacles, corners, and tight spaces, making woven hoses suitable for use in confined areas and complex installation environments.

High Resistance to Abrasion and Pressure

Woven hoses are known for their excellent resistance to abrasion and pressure. The weaving technique creates a strong and robust structure, capable of withstanding the rigors of demanding applications. These hoses are designed to handle high-pressure fluids and withstand constant movement and flexing without compromising their integrity. The woven construction provides enhanced resistance to wear and tear, ensuring long-term reliability and reducing the need for frequent replacements.

Temperature and Chemical Compatibility

Woven hoses exhibit excellent temperature and chemical compatibility. They are engineered to withstand a wide range of temperatures, from extreme cold to high heat, without losing their structural integrity or performance. Additionally, woven hoses are designed to resist the effects of various chemicals, including acids, bases, solvents, and oils. This versatility allows for their use in diverse industries, where different temperature ranges and chemical environments are encountered.

In conclusion, woven hoses offer a multitude of benefits due to their unique characteristics. Their flexibility and adaptability make them ideal for maneuvering in confined spaces, while their durability ensures long-term reliability. With high resistance to abrasion and pressure, woven hoses are capable of withstanding demanding applications without compromising performance. Moreover, their temperature and chemical compatibility make them versatile for use in diverse industries. By choosing woven hoses, industries can rely on their versatility and durability to ensure efficient and reliable operations.