In industrial production, high temperature and high pressure steam hose is a very important equipment. It is widely used in petroleum, chemical, pharmaceutical, food, manufacturing and other fields, and undertakes the key task of transporting high temperature and high pressure steam. This article will comprehensively introduce high temperature and high pressure steam hose from the aspects of material selection, process requirements, performance characteristics and application fields, to help readers better understand this important industrial equipment.

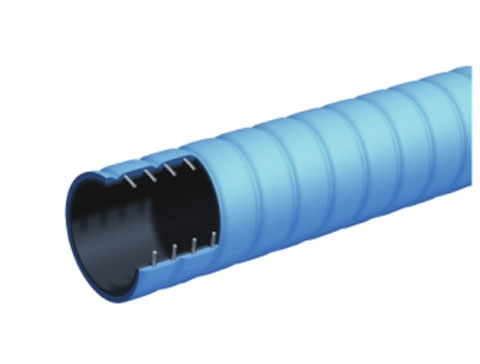

First, let's take a look at the material selection of high temperature and high pressure steam hose. Since it needs to withstand working conditions under high temperature and high pressure environment, the material selection of hose is crucial. Common high temperature resistant materials include polytetrafluoroethylene, polyimide, high temperature resistant rubber, etc., while high pressure resistant materials can choose high strength alloy steel wire, so that the hose has good pressure resistance and wear resistance. The lining material of the hose also needs to have good high temperature resistance, which can not only withstand the impact of high temperature steam, but also prevent steam leakage. Common lining materials include polytetrafluoroethylene, fluororubber, etc. Through scientific and reasonable material selection, the high temperature and high pressure resistance of the hose can be ensured.

Secondly, let's take a look at the process requirements of high temperature and high pressure steam hose. A series of process requirements need to be paid attention to during the manufacturing process of the hose to ensure its stable and reliable performance. First of all, the inner lining of the hose needs to adopt a seamless one-time molding process to avoid leakage problems at the joints. Secondly, the outer layer of the hose needs to have a certain pressure resistance and wear resistance, and a steel wire woven layer is generally added to increase strength. The connection method of the hose is also very critical. Common connection methods include flange connection, clamp connection, etc., which need to ensure that the connection is firm and not easy to loosen. In addition, the surface of the hose should be treated with anti-corrosion to extend its service life. Through strict process requirements, the quality and reliability of the hose can be guaranteed.

Next, let's take a look at the performance characteristics of high temperature and high pressure resistant steam hoses. The first is high temperature resistance. High temperature resistant hoses can maintain good working conditions under high temperature environments without softening, embrittlement, etc. The second is high pressure resistance. The hose needs to withstand the huge pressure from the steam pressure, so it needs to have good pressure resistance and can not deform or rupture under high pressure environments. In addition, the hose also needs to have wear resistance, corrosion resistance and other properties to cope with complex working environments.

Finally, let's explore the application areas of high temperature and high pressure resistant steam hoses. It is widely used in petroleum, chemical, pharmaceutical, food, manufacturing and other fields. In the petroleum industry, hoses are used to transport high temperature and high pressure steam and undertake important tasks in the oil processing process. In the chemical industry, hoses are used to transport various chemical media to ensure the safety and stability of the production process. In the pharmaceutical industry, hoses are used to transport high-temperature and high-pressure steam sterilization to ensure the quality requirements of medicines. In the food industry, hoses are used to transport various high-temperature and high-pressure foods to ensure the hygiene and safety of food. In the manufacturing industry, hoses are used for cooling cycles of high-temperature equipment, etc. Therefore, high-temperature and high-pressure steam hoses play an important role in various industries.

Through the introduction of this article, I believe that readers have a deeper understanding of high-temperature and high-pressure steam hoses. As an important industrial equipment, it guarantees the safety and stability of industrial production. With the continuous development of industrial production, the demand for high-temperature and high-pressure steam hoses is also increasing. Therefore, during use, we need to pay attention to selecting suitable hose materials, strictly controlling process requirements, and regularly testing and maintaining to ensure its normal operation. In this way, the role of high-temperature and high-pressure steam hoses can be better played, providing a strong guarantee for the safety and reliability of industrial production.

Next, let's take a look at the performance characteristics of high temperature and high pressure resistant steam hoses. The first is high temperature resistance. High temperature resistant hoses can maintain good working conditions under high temperature environments without softening, embrittlement, etc. The second is high pressure resistance. The hose needs to withstand the huge pressure from the steam pressure, so it needs to have good pressure resistance and can not deform or rupture under high pressure environments. In addition, the hose also needs to have wear resistance, corrosion resistance and other properties to cope with complex working environments.

Finally, let's explore the application areas of high temperature and high pressure resistant steam hoses. It is widely used in petroleum, chemical, pharmaceutical, food, manufacturing and other fields. In the petroleum industry, hoses are used to transport high temperature and high pressure steam and undertake important tasks in the oil processing process. In the chemical industry, hoses are used to transport various chemical media to ensure the safety and stability of the production process. In the pharmaceutical industry, hoses are used to transport high-temperature and high-pressure steam sterilization to ensure the quality requirements of medicines. In the food industry, hoses are used to transport various high-temperature and high-pressure foods to ensure the hygiene and safety of food. In the manufacturing industry, hoses are used for cooling cycles of high-temperature equipment, etc. Therefore, high-temperature and high-pressure steam hoses play an important role in various industries.

Through the introduction of this article, I believe that readers have a deeper understanding of high-temperature and high-pressure steam hoses. As an important industrial equipment, it guarantees the safety and stability of industrial production. With the continuous development of industrial production, the demand for high-temperature and high-pressure steam hoses is also increasing. Therefore, during use, we need to pay attention to selecting suitable hose materials, strictly controlling process requirements, and regularly testing and maintaining to ensure its normal operation. In this way, the role of high-temperature and high-pressure steam hoses can be better played, providing a strong guarantee for the safety and reliability of industrial production.