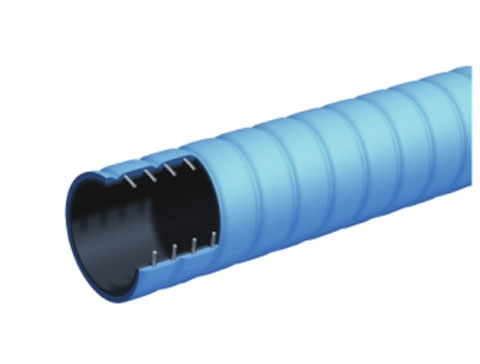

A customer request: The tube can be rolled up mechanically. Length: 30~100m, inner diameter 150mm, pressure 350KG Flow rate: 300~450 cubic meters per hour Medium: underground gravel slag, (two rounds of grinding), about 30% of the slag, the largest conveying particle is oval Gravel (sharp edge), usually used for pipes. It will be replaced in a few days. After using the latest Litong wear-resistant pipe, the customer's production efficiency has been greatly improved. Another type of Litong's wear-resistant hose is custom developed for special industries, that is, LT1306UPE super wear-resistant concrete conveying hose, because it uses a special inner rubber material UPE (ultra-high molecular polyethylene) as its wear-resistant layer. Therefore, in terms of service life, it can reach several times that of ordinary wear-resistant hoses. It can pass most corrosive mixed media such as acid-base, hydrogen sulfide, etc., and its excellent characteristics make it free from the corrosion of acidic substances in concrete or mud. High pressure steam hose price PTFE hose has the characteristics of acid and alkali resistance, resistance to various organic solvents, and is almost insoluble in all solvents, which can protect parts from being corroded by any chemicals; the excellent non-flammability of PTFE hose, The oxygen limit index is below 90, and the incineration grade is V-0... It solves the shortcomings of the previous steel-lined PTFE pipes and fittings that cannot be used under negative pressure, and has been widely used in many distillation and other high-temperature and high-negative pressure systems. There are many categories of high-pressure wear-resistant pipes that we often talk about. This time we mainly talk about reinforced concrete pump hoses, which are one of the types of concrete conveying hoses. And the oxidation resistance is greatly improved, the efficiency of transporting concrete slurry mixture is several times higher than that of traditional slurry pipes, and it is more suitable for concrete pouring sites and has become the mainstream hose in today's concrete pouring sites.The pressure from steam is important for steam hoses because it determines the temperature conditions the hose will be used in. If steam is saturated, its temperature is directly related to its pressure. The temperature can be determined from the saturated steam table. However, if the steam is superheated, we must know the degree of superheat in order to determine the actual temperature the hose must withstand. Otherwise, indeterminate or wrong temperatures can drastically reduce the useful life of the steam hose. When the wear-resistant pipe assembly is installed, it should be fixed with a regular pipe frame, and the pipe frame in contact with the high-pressure pipeline and pipe fittings must be installed with the corresponding protective sleeve according to the design requirements. When installing the boot, the pipe ends should be chamfered. When installing the sealing gasket, do not put the metal wire in advance. Lubricating oil should be applied to the nozzle and the gasket surface first, and the metal cushion should be accurately placed in the sealing seat. The pipe diameter is small and low pressure, so the flange connection will not be visible.More information about the price of high pressure steam hose will be updated gradually, so stay tuned. Tags you may be concerned about: steam high pressure price hose Related tags: Number of articles: Steam (84) High Pressure (269)